BIOFORM nanometer carrier packing

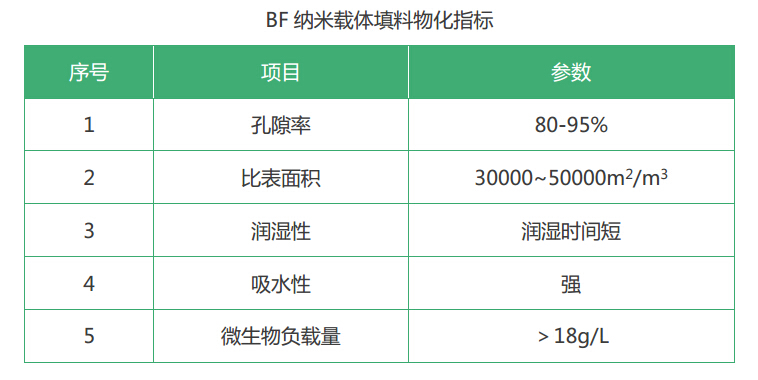

The bioactive foam carrier filler developed by Biwofeng is a sponge cubic filler modified by polyurethane foam. Through the combination of polyurethane materials and nanoparticles, the mechanical properties, chemical stability and aging resistance of polyurethane foam plastics were improved. With a reactive functional group, the reactive group can interact with the amino acid residue of the microbial peptide chain to form an ionic bond or a covalent bond which immobilizes the microorganism and the enzyme on the carrier. It has the advantages of high porosity, good wear resistance, good hydrophilicity and high microbial adhesion rate.

The introduction of the "suspension space" on the carrier aims to reduce the space barrier and provide a broad metabolic proliferation space for the immobilized microorganisms so that the sewage, air and microorganisms can be fully contacted. Biofilms maintain good activity and interstitial variability and do not stick together.

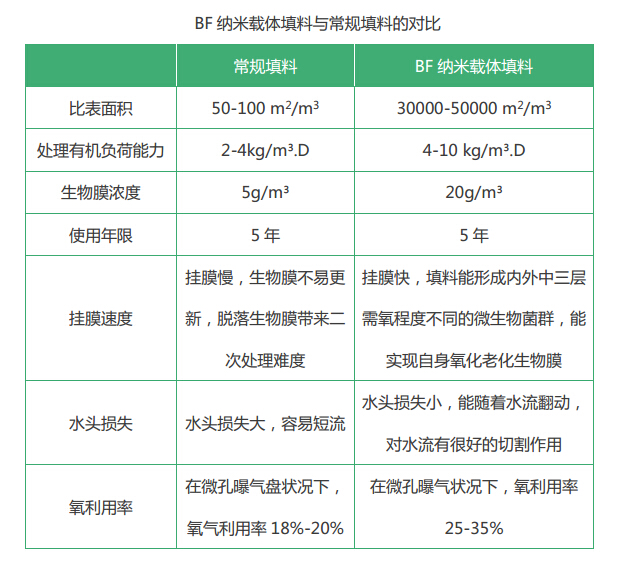

The density of the carrier is close to the density of water and the carrier is suspended in water which is used in the fluidization tank. It has the characteristics of large specific surface area, high biomass per unit volume with uniform contact, fast mass transfer rate and low-pressure loss. Because it can maintain high concentration of biomass, it has advantages, such as large volume load, small floor space, low construction cost, high impact load resistance, no sludge expansion, high oxygen utilization rate and low operating cost. It is suitable for the treatment of high-concentration organic wastewater such as refining, chemical engineering, pharmaceuticals, printing and dyeing, brewing, leather and papermaking.

The three-dimensional porous structure of the carrier can breed and grow microbial populations with different aerobic levels. The externally attached microorganisms can quickly consume dissolved oxygen in the water body and transfer the metabolites. The microorganisms in the middle of the carrier continue to decompose the metabolites of the upper stage and further dissolve oxygen. When the internal filling structure is achieved, anaerobic microorganism population is formed which allows the carrier to achieve anaerobic anoxia and aerobic microorganism structure from the inside and outside. The nitrification and denitrification can be carried out simultaneously which has a good effect of removing macromolecular organics, total nitrogen and total phosphorus, especially suitable for the treatment of industrial wastewater with high ammonia. nitrogen.

National Service Hotline:400-608-6866 Online

特点

The specific surface area of the filler is large and the microbial flora can grow rapidly on the surface to form a highly active biofilm, which effectively avoids the loss of microbial flora with slow propagation rate and low yield, such as nitrifying bacteria.

It significantly improves the efficiency of biochemical system processing and stability of biochemical pool.

It effectively inhibits the toxic effects of refractory substances and toxic substances on microbial flora.

It significantly enhances the tolerance ability of the system for load, shock of toxic inhibitory substances and changes in pH and temperature which effectively reduces the production of excess sludge.

Simultaneous nitrification and denitrification are achieved.

Package product

Applications